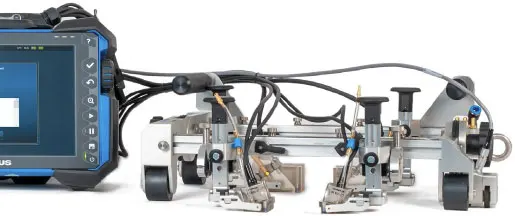

OmniScan X3 64 flaw detector for sale delivers improved power and performance to Olympus field-proven phased array ultrasonic testing (PAUT)

Product Description

Complete package includes:

Additional probes;

The new OmniScan X3 64 flaw detector delivers improved power and performance to Olympus field-proven phased array ultrasonic testing (PAUT) product line. This 64-channel instrument has the pulser capacity to drive phased array (PA) probes with a larger number of elements, increasing the data acquisition speed for total focusing method (TFM) imaging. Users can exploit its increased capabilities to expand and diversify their application portfolio.

The high portability and enhanced performance of the OmniScan X3 64 flaw detector increase inspection productivity. It can process TFM images up to four times as fast as its predecessor, yet comes in the same rugged and easily transportable box. On job sites with limited or restricted space, users will appreciate that the OmniScan X3 64 unit is compact and less cumbersome than other 64-channel devices. Inspectors can also remain on site longer and perform bigger scanning jobs without transferring data, thanks to the large 1 TB onboard storage.

Facilitating complex and thick part or weld applications, the instrument full 64-element aperture PA and 128-element aperture TFM enables users to optimize advanced Dual Linear Array (DLA) and Dual Matrix Array (DMA) probes. To save time during setup, all models in the OmniScan X3 series have integrated DLA and DMA support.

Smaller defects are easier to distinguish using the OmniScan X3 64 flaw detector high resolution PA and TFM imaging. Accommodating lower frequency probes, the OmniScan X3 64 unit can increase penetration in attenuative materials while reducing signal saturation. These improved detection capabilities assist monitoring for early-stage flaws, such as high-temperature hydrogen attack (HTHA).

When applications require advanced analysis, the entire PA inspection workflow can be performed using Olympus WeldSight software for greater efficiency. With the WeldSight Remote Connect app installed on the OmniScan X3 64 unit, users can instantly view the acquired data on a PC, exploiting the customizable user interface and software tools that facilitate specialized inspection procedures, including new-fabrication welds in pressure vessels

The OmniScan X3 flaw detector combines the essential tools needed for PAUT inspections, such as TOFD, two UT channels, eight groups and 16:64PR, 16:128PR and 32:128PR configurations, with powerful innovations, including:

WORK MORE EFFICIENTLY AND CONFIDENTLY

Improved Agility and Mobility

When on the job site, you need equipment that is compact and easy to transport. Smaller and less cumbersome than other typical 64-channel devices, the OmniScan X3 64 flaw detector offers true portability, providing increased convenience and flexibility for jobs where space is limited.

Feel Supported, Wherever You Go

Feel Supported, Wherever You GoOffering proven reliability, the OmniScan X3 64 unit is built tough to withstand harsh environments and challenging inspection demands. Backed by our global customer support, geolocation, and wireless connectivity, you can be productive and efficient in the field.

- IP65 certified rain and dust proof

- User-replaceable cooling fan

- Onboard GPS*

- Software updates via the Olympus Scientific Cloud (OSC)

Minimize the Learning Curve

This OmniScan unit has the same user-friendly interface and streamlined, intuitive menu structure of the OmniScan X3 flaw detector. Compatible with OmniScan setup files, it can load your parameters from other OmniScan X3 models so you can reuse your preset configurations.

Accomplish More in Less Time

The OmniScan X3 64 internal storage holds larger amounts of inspection data (up to 1 TB), enabling you to perform bigger scanning jobs and stay on site longer without needing to transfer your files.

MAXIMIZE YOUR PRODUCTIVITY

OPTIMIZED INSPECTION WORKFLOW

Facilitate complex and specialized inspection procedures, such as new fabrication welds in pressure vessels, using Olympus’ WeldSight in tandem with OmniScan X3 64. Installing the WeldSight Remote Connect app enables you to control the acquisition and instantly view your phased array (PA) data on a PC. Increase productivity by exploiting the customizable user interface, advanced analysis tools and optimizing your equipment configuration to match your needs

Facilitate complex and specialized inspection procedures, such as new fabrication welds in pressure vessels, using Olympus’ WeldSight in tandem with OmniScan X3 64. Installing the WeldSight Remote Connect app enables you to control the acquisition and instantly view your phased array (PA) data on a PC. Increase productivity by exploiting the customizable user interface, advanced analysis tools and optimizing your equipment configuration to match your needs

Ease Challenging Applications

Detect and distinguish smaller defects, using the high-quality imaging supported by the instrument’s 64-channel capacity. Using larger, more powerful PA probes, you can attain a better resolution deeper in the part and clearly see minute flaws such as high-temperature hydrogen attack (HTHA) before they reach the critical phase.

Detect and distinguish smaller defects, using the high-quality imaging supported by the instrument’s 64-channel capacity. Using larger, more powerful PA probes, you can attain a better resolution deeper in the part and clearly see minute flaws such as high-temperature hydrogen attack (HTHA) before they reach the critical phase.

TOTAL FOCUSING METHOD (TFM) MADE ACCESSIBLE

Perform Faster TFM The improved speed and efficiency of the OmniScan X3 64 model’s TFM makes it more feasible to incorporate as a regular part of your inspection process. Using a full 64-element aperture increases the acquisition speed of TFM, which is further optimized by the system’s sparse firing algorithm.Offering exponentially faster acquisition rates, our improved TFM provides you with vital data for your analysis:

Reach Your Peak Potential

Use the clear, crisp imaging provided by 64- channel TFM to achieve more precise sizing and flaw positioning. Expand your potential for specialized applications using the unit’s up to 128-element aperture capacity to meet challenging inspection demands.

Use the clear, crisp imaging provided by 64- channel TFM to achieve more precise sizing and flaw positioning. Expand your potential for specialized applications using the unit’s up to 128-element aperture capacity to meet challenging inspection demands.

Improved Performance in Attenuative Materials

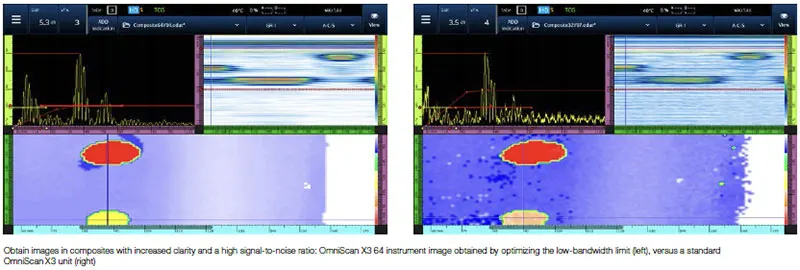

The OmniScan X3 64 flaw detector offers better sound penetration in materials with high attenuation. Its 1000 ns pulse width frequency capacity and lower 0.2 MHz bandwidth enables you to use lower frequency probes, improving your ability to scan the entire volume of highly attenuative materials, such as fiberglass and other composites.

Achieve Precision in Fiberglass and Composites

Offering lower pulse voltage limit options, the OmniScan X3 64 flaw detector enables you to eliminate front wall echo saturation and see complete echo waveforms. Use this capability to exploit all detection options, including the peak and edge, making your analysis more reliable

OMNISCAN X3 64 PHASED ARRAY SPECIFICATIONS

| Housing and General | ||

| Size (W × H × D) | 335 mm × 221 mm × 151 mm (13.2 in. × 8.7 in. × 5.9 in.) | |

| Weight | 5.7 kg (12.6 lb) (with 1 battery) | |

| Onboard Storage | 1 TB internal SSD storage, extendable as needed with an external USB drive; 25 GB maximum file size | |

| Storage Devices | SDHC™ and SDXC™ cards or most standard USB storage devices | |

| GPS | Yes (unless specified otherwise for some regions) | |

| Wireless Connection | Yes (wireless LAN dongle included in the package | |

| Connectors | 1 PA connector, 2x UT channels (2 P/R connectors each) | |

| Number of Groups | 8 groups | |

| Certifications | ISO 18563-1:2015 ISO 22232-1:2020 |

|

| Display | TFT LCD with resistive touch screen, 269 mm (10.6 in.), 1280 × 768 pixels | |

| Battery | 2 lithium-ion battery (only 1 included at purchase), 93 Wh | |

| Battery Life | 5 hours using 2 batteries (hot-swap capable) | |

| Inputs and Outputs | ||

| Ports | 2 USB ports (one hidden behind the battery), 1 USB 3.0, HDMI video output, SDHC memory card, and Ethernet communication port | |

| Encoders | 2-axis encoder line (quadrature or clock/direction), 3rd encoder ready | |

| Digital Input and outputs | 6 digital inputs, TTL (enabling acquisition ON/OFF) and 5 digital outputs, TTL | |

| PA/UT Configuration | ||

| Frequency | Effective Digitizing Frequency | Up to 100 MHz |

| Max PRF | 20 kHz | |

| Data Specifications | ||

| Processing | Maximum Number of A-Scan Data Points | Up to 16,384 |

| Rectification | RF, full wave, half wave+, half wave- | |

| Filtering | Selection of low-pass (UT only), band-pass, and high-pass filters, and averaging | |

| Video Filtering | Smoothing (adjusted to the probe frequency range) | |

| TCG Range | PA (standard): 40 dB per step of 0.1 dB UT: 100 dB per step of 0.1 dB |

|

| TCG Maximum Slope |

PA (standard): 40 dB/10 ns UT: 40 dB/10 ns |

|

| Acoustic Specifications | |||

| PA Channel | UT Channels | ||

| Pulser | Voltage | 10 Vpp, 20 Vpp, 40 Vpp, 80 Vpp, 120 Vpp, and 160 Vpp | 85 V, 155 V, and 295 V |

| Pulse Shape | Bipolar square pulse | Negative square pulse | |

| Pulse Width | Adjustable from 30 ns to 1000 ns; resolution of 2.5 ns | Adjustable from 30 ns to 1,000 ns; resolution of 2.5 ns | |

| Receiver | Gain Range | 0 dB to 80 dB maximum input signal; 900 mVpp (full-screen height) | 0 dB to 120 dB maximum input signal; 30 Vpp (full-screen height |

| System Bandwidth | 0.2 MHz to 26.5 MHz | 0.25 MHz to 28.5 MHz | |

| Beam Formation | Scan Type | Single, linear, sectorial, compound, and TFM | |

| Maximum Aperture | 64 elements | ||

| Number of Focal Laws | Up to 1024 total (512 per group maximum) | ||

| TFM/FMC | |||

| Supported Wave Sets | Pulse echo: L-L, TT, and TT-TT Self-Tandem: TT-T, LL-L, LT-T, TL-T, TT-L, TTT-TT, and TL-L |

||

| Parallel Multimode TFM | 4 simultaneous TFM groups (wave sets) | ||

| Live Envelope Processing | Yes | ||

| Maximum Aperture | 128-element extended aperture | ||

| Image Resolution | Up to 1024 × 1024 (1 MM points) (for each TFM wave set) | ||

| Operating Environment | |||

| Ingress Protection Rating | IP65 certified (completely protected against dust and water jets from all directions (6.3 mm nozzle)) | ||

| Shockproof Rating | Drop tested according to MIL-STD-810G | ||

| Operating Temperature | −10°C to 45° C (14 °F to 113°F) | ||

|

Standard Inclusions |

|||