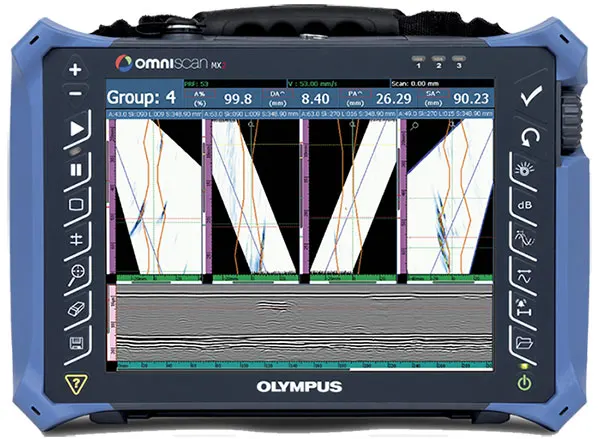

Olympus Omniscan MX2 16:128 Phased Array Flaw Detector for sale, been inspected, certified and guaranteed by authorized Olympus, ready to working order for inspection and analysis

Product Description

Sale Omniscan MX2 16:128 Phased Array Flaw Detector, been certified and guaranteed by authorized Olympus, ready to working order for inspection and analysis. This instuments is in complete working order, 16:128 Module installed, rarely used and never had any underlying problems, everything still in excellent perfect working condition.

This Omniscan MX2 16:128 Phased Array sale packages;

if you are looking for an Omniscan MX2 Phased Array up to 32 probes, then we have for sale OmniScan MX2 32:128PR phased array, sale included weld software option, ToFD software option and Multigroup software option. Suitable for weld inspection, composite inspection, corrosion inspection, etc

The latest generation of ultrasonic flaw detector includes a larger and brighter touch screen interface that lets you get the job done in record time. The OmniScan MX2 speeds up your setup process with an intuitive step-by-step wizard designed to get you testing quickly. The powerful software features allow for efficient manual inspections and high-performance automated inspections. Lightning performance, faster data transfer rates and expanded capabilities through additional software programs combine to improve workflow and increase inspection efficiency.

The high-end, scalable platform is universally compatible with over 10 phased array and ultrasound modules, making the OmniScan MX2 ultrasonic flaw detector the confident choice for the future. When combined with other critical components from the complete range of solutions from Olympus, you can create a complete inspection system for your application-specific needs. The OmniScan MX2. This phased array flaw detector features an entirely new design with a large, bright 10.4 inch LCD touch screen that provides simple and fast navigation, enhanced text input functionality, and easy parameter settings. In combination with new powerful software features, high-capacity data storage and fast data transfer, the OmniScan MX2 provides powerful inspection capabilities for manual and automated phased array applications.

The OmniScan MX2's innovative touch screen interface with full screen mode achieves maximum visibility and provides intuitive operation for most common operator functions such as menu selection, zooming, gate selection, cursor movement, and text and value input. Wizards during setup and calibration, a high S-scan and A-scan display refresh rate, and a fast pulse repetition frequency (PRF) make the OmniScan MX2 an efficient inspection tool. High-speed data transfer can be achieved with an SD card or through USB ports.

The OmniScan Phased Array family comes with all software options including Multigroup, Time-of-Flight Diffraction (TOFD) and the new Weld Overlay Wizard software that facilitates the creation of industry standard weld overlays for analysis assistance and volumetric flaw placement.

The OmniScan MX2 is a modular instrument that is fully compatible with the thousands of phased array modules already in the field. Its technology platform allows for fast and easy software and phased array module upgrades ranging from to 16:64 to 32.128 configurations. The OmniScan MX2 can be used with a full range of phased array probes, scanners, and accessories, making Olympus the phased array solutions provider of choice for the petrochemical, aerospace, and other industrial markets.

Girth Weld Inspection

Girth Weld InspectionThe OmniScan PA is at the heart of the Olympus manual and semiautomated circumferential weld-inspection solutions developed for the oil and gas industry. These phased array systems, which are certified for tube inspection in compliance with ASME, API, and other code criteria, offer superior inspection speed and detection, and facilitate interpretation of indications.

Pressure Vessel Weld Inspection

Pressure Vessel Weld InspectionA complete inspection of pressure vessel welds can be performed in a single scan using an OmniScan PA and a motorized scanner such as the WeldROVER. By combining TOFD and PA in a single inspection pass, a significant reduction in inspection time can be achieved as compared with conventional raster scanning or radiography. Further-more, inspection results are available immediately, enabling you to detect problems with welding equipment and fix them right away.

Weld Inspection of Small-Diameter Pipes

Weld Inspection of Small-Diameter PipesWhen coupled with the COBRA manual scanner, the OmniScan flaw detector is capable of inspecting pipes ranging from 0.84 in. OD to 4.5 in. OD. With its very slim design, this manual scanner is able to inspect pipes in areas with limited access. Adjacent obstructions such as piping, supports, and structures can be as close as 12 mm (0.5 in.).

Manual and Semiautomated Corrosion Mapping

Manual and Semiautomated Corrosion MappingThe OmniScan PA sytem with the HydroFORM scanner is designed to offer the best inspection solution for detecting wall-thickness reduc-tions resulting from corrosion, abrasion, and erosion. In addition, it detects mid-wall damage such as hydrogen-induced blistering and manufacturing-induced laminations, and easily differentiates these anomalies from loss of wall thickness. For this application, phased array ultrasound technology offers supe- rior inspection speed, data point density, and detection

Composite Inspection

Composite InspectionParts made of laminate composite materials pose an inspection challenge due to their various shapes and thicknesses. Olympus offers complete solutions for the inspection of carbon-fiber-reinforced polymer structures. These solutions are based on the OmniScan flaw detector, the GLIDER scanner, and dedicated probes and wedges designed for CFRP flat panel and radius inspection.

Corrosion Mapping Inspection

The OmniScan PA system with the HydroFORM scanner is designed to offer the best inspection solution for the detection of wall-thickness reductions resulting from corrosion, abrasion, and erosion. For this application, phased array ultrasound technology offers superior inspection speed, data point density, and detection

Design with NDT SetupBuilder

NDT SetupBuilder design software is an integral part of the Olympus line of automated and semiautomated ultrasonic testing products. NDT supervisors can use NDT SetupBuilder software to simulate the inspection strategy in order to determine the appropriate number of beams and angles. This configuration can be imported to the OmniScan MX2, thereby reducing configuration time and manipulation error

Acquisition OmniScan MX2

The OmniScan MX2 flaw detector provides powerful inspection capabilities for manual and automated applications. It can be used with a full range of probes, scanners, and accessories, making Olympus the provider of choice for petrochemical, aerospace, and other industrial market

Analysis OmniPC software

This OmniPC software is the most efficient and affordable option for OmniScan data analysis, and features the same analysis and reporting tools provided in the OmniScan onboard software, with the added flexibility to be run on a personal computer

OmniScan MX2 Mainframe Specifications |

||

| Overall dimensions (W x H x D |

325 mm x 235 mm x 130 mm (12.8 in. x 9.3 in. x 5.1 i |

|

| Data Storage | ||

| Storage devices | SDHC card, most standard USB storage devices, or fast Ethernet | |

| Data file size | 300 MB | |

| I/O Ports | ||

| USB ports | 3 | |

| Audio alarm | Yes | |

| Video output | Video out (SVGA | |

| Ethernet | 10/100 Mbps | |

| I/O Lines | ||

| Encoder | 2-axis encoder line (quadrature, up, down, or clock/direction) | |

| Digital input | 4 digital TTL inputs, 5 V | |

| Digital output | 4 digital TTL outputs, 5 V, 15 mA | |

| Acquisition on/off switch | Remote acquisition enabled TTL, 5 V | |

| Power output line | 5 V, 500 mA power output line (short-circuit protected) | |

| Alarms | 3 TTL, 5 V, 15 mA | |

| Analog output | 2 analog outputs (12 bits) ±5 V in 10 kΩ | |

| Pace input | 5 V TTL pace input | |

| Display | ||

| Display size | 26.4 cm (10.4 in.) (diagonal) | |

| Resolution | 800 pixels x 600 pixels | |

| Brightness | 700 cd/m2 | |

| Number of colors | 16 million | |

| Type | TFT LCD | |

| Power Supply | ||

| Battery type | Smart Li-ion battery | |

| Number of batteries | 1 or 2 (battery chamber accommodates two hotswappable batteries) | |

| Battery life | Minimum 7 hours with two batteries | |

| Environmental Specifications | ||

| Operating temperature range |

-10 °C to 45 °C (14 ºF to 113 ºF) |

|

| Storage temperature range | –20 °C to 60 °C (–4 ºF to 140 ºF) with batteries –20 °C to 70 °C (–4 ºF to 158 ºF) without batteries |

|

| Relative humidity | Max. 70% RH at 45°C noncondensing | |

| Ingress Protection Rating | Designed for IP66 | |

| Shockproof rating | Drop-tested according to MIL-STD-810G 516.6 | |

| MX2 Module Compatibility | ||

| MXU 4.1R8 and later | OMNI-M2-PA32128PR | |

| MXU 4.0 and later | OMNI-M2-PA1664 OMNI-M2-PA16128 OMNI-M2-PA32128 OMNI-M2-UT-2CH |

|

| MXU 3.1 and MXU 4.1R9 and later |

OMNI-M-UT-8CH | |

| Phased Array Module Specifications | |||

| Overall dimensions (W x H x D |

226 mm x 183 mm x 40 mm (8.9 in. x 7.2 in. x 1.6 in.) |

||

| Weight | 1.6 kg (3.5 lb) | ||

| Connectors | 1 Phased Array connector: Olympus PA connector 2 UT connectors: LEMO 00 |

||

| Number of focal laws | 256 | ||

| Probe recognition | Automatic probe recognition | ||

| Pulser/Receiver | |||

| Aperture | 32 elements* | ||

| Number of elements | 128 elements* | ||

| Pulser | PA Channels | UT Channels | |

| Voltage | 40 V, 80 V, and 115 V | 95 V, 175 V, and 340 V | |

| Pulse width | Adjustable from 30 ns to 500 ns, resolution of 2.5 ns | Adjustable from 30 ns to 1,000 ns; resolution of 2.5 ns | |

| Output impedance (32:128PR model | 35 Ω in in pulse-echo mode 30 Ω in pitch-catch mode |

<30 Ω | |

| Output impedance (all other models) | 25 Ω | <30 Ω | |

| Receiver | PA Channels | UT Channels | |

| Gain | 0 dB to 80 dB, maximum input signal 550 mVp-p (full-screen height) | 0 dB to 120 dB maximum input signal 34.5 Vp-p (full-screen height) | |

| Input impedance (32:128PR model) | 50 Ω in pulse-echo mode 90 Ω in pitch-catch mode |

60 Ω in pulse-echo mode 50 Ω in pitch-catch mode |

|

| Input impedance (all other models) | 65 Ω | 60 Ω in pulse-echo mode 50 Ω in pulse-receive mode |

|

| System bandwidth | 0.6 MHz to 18 MHz (–3 dB) | 0.25 MHz to 28 MHz (–3 dB) | |

| Beamforming | |||

| Scan type | Sectorial and linear | ||

| Group quantity | Up to 8 | ||

| Data Acquisition | |||

| Digitizing frequency | 100 MHz | ||

| Maximum pulsing rate | Up to 10 kHz (C-scan) | ||

| Data Processing | PA Channels | UT Channels | |

| Number of data points | Up to 8,192 | ||

| Real-time averaging | 2, 4, 8, 16 | 2, 4, 8, 16, 32, 64 | |

| Rectifier | RF, full wave, half wave +, half wave – | ||

| Filtering | 3 low-pass, 6 bandpass, and 4 high-pass filters. | 3 low-pass, 6 band-pass, and 3 high-pass filters (3 low-pass filters when configured in TOFD) | |

| Video filtering | Smoothing (adjusted to probe frequency range) | ||

| Data Visualization | |||

| A-scan refresh rate | Real time: 60 Hz | ||

| Data Synchronization | |||

| On internal clock | 1 Hz to 10 kHz | ||

| On encoder | On 2 axes: from 1 to 65,536 steps | ||

| Programmable Time-Corrected Gain (TCG) | |||

| Number of points | 32: One TCG curve per focal law | ||

| Alarms | |||

| Number of alarms | 3 | ||

| Conditions | Any logical combination of gates | ||

| Alarm outputs | 2 | ||

OmniScan MX2 Video Overview

Download documents