Olympus BondMaster 600 MultiMode Ultrasonic Bond Tester for sale, still like new in perfect working order.

Product Description

Olympus Panametrics BondMaster 600M Ultrasonic Bond Thickness Flaw Detector NDT. Like New! All Software Options! MIA, P/C, Resonance Modes! does not come with a probe, screen is in perfect condition.

Olympus BondMaster 600 MultiMode Ultrasonic Bond Tester sale includes:

BondMaster 600 Multimode Bond Tester | High Performance through Intuitive Operation

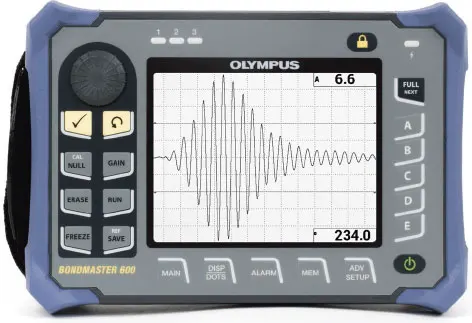

The BondMaster 600 delivers a powerful combination of multiple mode bond testing software and highly advanced digital electronics, providing consistently crisp and high-quality signals. Whether you are inspecting honeycomb composite, metal-to-metal bonds, or laminate composite, the BondMaster 600 offers exceptional ease-of-use thanks to its direct-access keys and streamlined interface that features convenient presets for common applications. The enhanced user interface and simplified workflow of the BondMaster 600 offers archiving and reporting that are accessible to any level of user.

The resolution and brightness of the 5.7-inch VGA screen on the BondMaster 600 handheld bond tester becomes even more apparent when switched into full-screen mode. Activated by the simple touch of a key, the full-screen mode is always accessible regardless of the display mode or inspection method you are using. The BondMaster 600 bond tester is programmed for a range of standard inspection methods, including pitch catch RF, pitch-catch impulse, pitch-catch swept, resonance, as well as a notably improved mechanical impedance analysis (MIA) method.

Portable, Lightweight, and Ergonomic

The ergonomic design of the BondMaster 600 is convenient for difficult-to-access inspection locations. For inspection in tight spaces, the factory-installed hand strap provides maximum comfort while maintaining access to the most critical functions.

Field Proven

The BondMaster 600’s case, based on a rugged, field-proven design, is world-renowned for withstanding the harshest, most demanding inspection conditions. The BondMaster 600 with its long battery life, airtight and water-resistant enclosure, high-friction bumpers, and dual-duty support stand/hook is a valuable tool for challenging inspection jobs.

Key Features

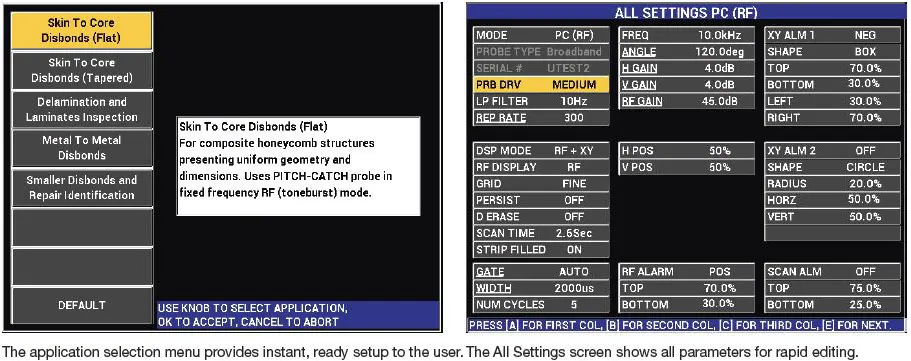

One of the major assets of the BondMaster 600 bond tester is its unprecedented ease of use. Its streamlined and user-friendly interface was developed by incorporating innovative features from other Olympus products and combining them with several new functions, including the Application Selection (presets) menu, the All Settings direct modification screen, and the ability to calibrate signals while in Freeze mode. All the advantages offered by the BondMaster 600 interface are available in 15 languages

The BondMaster 600 bond tester features a comprehensive set of direct-access keys, enabling instant adjustment of commonly used parameters such as gain, full-screen mode, display mode (RUN), and more. Signals are displayed in eight vivid and identifiable color schemes, and the screen’s enhanced visibility in indoor and outdoor conditions helps reduce operator eye fatigue.

Signal Quality Beyond Comparison

Enhance Your Honeycomb Composite Inspection Capability

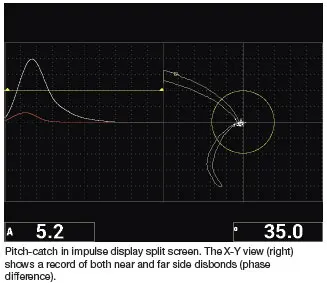

During bond testing inspections, the pitch-catch probe produces flexural plate waves and compression waves and compares changes in the signal amplitude between the probe’s transmitter and receiver as it passes over the inspected part, detecting disbonds on both the near and far side. The BondMaster® 600 bond tester offers three Pitch-Catch mode options: RF (fixed frequency waveform), Impulse (legacy view featuring an envelope filter), or Swept (sweeping through a selected frequency range). The Pitch-Catch menus of the BondMaster 600 bond tester have been optimized to provide fast access to the parameters that are adjusted most frequently during calibration and inspection. The real time readings provide instantaneous information on the signal amplitude or phase, enabling you to interpret flaws more easily. The new Auto Gate mode automatically detects the best “gate” position based on the RF or impulse signal, reducing operator error and maximizing the results.

During bond testing inspections, the pitch-catch probe produces flexural plate waves and compression waves and compares changes in the signal amplitude between the probe’s transmitter and receiver as it passes over the inspected part, detecting disbonds on both the near and far side. The BondMaster® 600 bond tester offers three Pitch-Catch mode options: RF (fixed frequency waveform), Impulse (legacy view featuring an envelope filter), or Swept (sweeping through a selected frequency range). The Pitch-Catch menus of the BondMaster 600 bond tester have been optimized to provide fast access to the parameters that are adjusted most frequently during calibration and inspection. The real time readings provide instantaneous information on the signal amplitude or phase, enabling you to interpret flaws more easily. The new Auto Gate mode automatically detects the best “gate” position based on the RF or impulse signal, reducing operator error and maximizing the results.

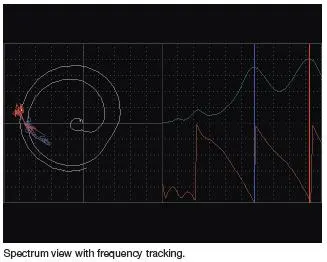

The BondMaster 600 Pitch-Catch Swept mode not only features improved signal quality but also has a new “Spectrum” representation. This new view displays the live amplitude and phase of the signal compared to the frequency range. Two new frequency markers (called frequency tracking) enable you to observe the behavior of two specific frequencies so that you can choose the best detection parameters for a specific application. This new tool is ideal for developing procedures or new applications

The BondMaster 600 Pitch-Catch Swept mode not only features improved signal quality but also has a new “Spectrum” representation. This new view displays the live amplitude and phase of the signal compared to the frequency range. Two new frequency markers (called frequency tracking) enable you to observe the behavior of two specific frequencies so that you can choose the best detection parameters for a specific application. This new tool is ideal for developing procedures or new applications

Resonance Mode Presets to Meet Your Needs

Easy Inspection of Metal-to-Metal Bonds and Laminate Composites

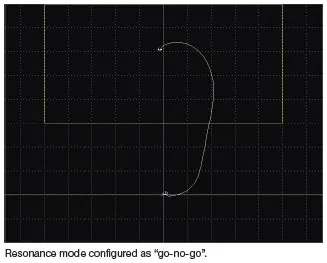

Resonance mode measures the changes in phase and amplitude of the propagating/standing wave within the probe. Resonance probes are narrow bandwidth contact transducers, and the change in probe crystal impedance is represented in the X-Y display of the BondMaster 600 bond tester. Resonance mode is a very simple and reliable way to detect delamination. Often, the depth of delamination can be estimated from signal phase rotation. Resonance mode on the BondMaster 600 bond tester is remarkably easy to operate, due in large part to its factory presets for laminate composite and metal-to-metal disbond applications.

Resonance mode measures the changes in phase and amplitude of the propagating/standing wave within the probe. Resonance probes are narrow bandwidth contact transducers, and the change in probe crystal impedance is represented in the X-Y display of the BondMaster 600 bond tester. Resonance mode is a very simple and reliable way to detect delamination. Often, the depth of delamination can be estimated from signal phase rotation. Resonance mode on the BondMaster 600 bond tester is remarkably easy to operate, due in large part to its factory presets for laminate composite and metal-to-metal disbond applications.

Simplified Calibration through an Optimized Interface

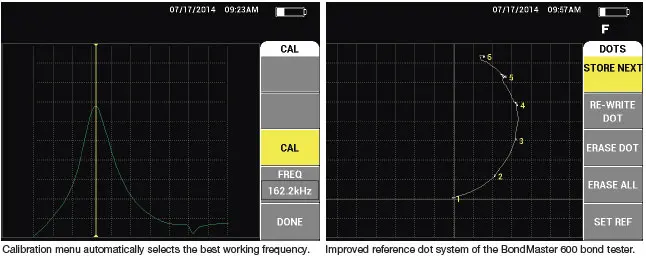

Calibrating the Resonance mode on the BondMaster 600 bond tester has been simplified to a minimum number of steps. First, the optimum operating frequency for the probe is selected through the single-step calibration menu, and then the streamlined interface of the BondMaster 600 bond tester and the ability to calibrate from frozen signals make the final calibration quick and simple.

Calibrating the Resonance mode on the BondMaster 600 bond tester has been simplified to a minimum number of steps. First, the optimum operating frequency for the probe is selected through the single-step calibration menu, and then the streamlined interface of the BondMaster 600 bond tester and the ability to calibrate from frozen signals make the final calibration quick and simple.

Once calibrated, the improved signal reference and reference dot system of the BondMaster 600 bond tester enable you to easily track critical signals on the display during inspection. Moreover, its reference points system is so flexible that you can fine-tune the calibration without having to rerecord the points.

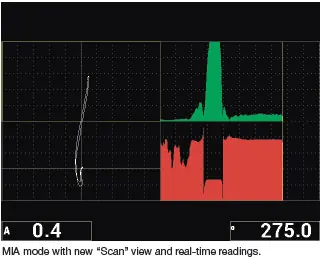

The bond testing mechanical impedance analysis (MIA) method measures the mechanical impedance, or stiffness, of a material. MIA probes emit a fixed, audible frequency. Changes in materiastiffness are indicated as signal amplitude and phase changes in the X-Y view of the BondMaster 600 bond tester. The small probe tip used with MIA, coupled with the highperformance

The bond testing mechanical impedance analysis (MIA) method measures the mechanical impedance, or stiffness, of a material. MIA probes emit a fixed, audible frequency. Changes in materiastiffness are indicated as signal amplitude and phase changes in the X-Y view of the BondMaster 600 bond tester. The small probe tip used with MIA, coupled with the highperformance

electronics of the BondMaster 600 bond tester, make detecting very small disbonds in honeycomb composite much easier than with other methods. Moreover, the extended MIA frequency range of the BondMaster 600 bond tester (2 kHz to 50 kHz) obtains maximum results, even for far side disbonds. The BondMaster 600 bond tester features a simple MIA calibration wizard that guides you in selecting the best possible frequency for detecting smaller and otherwise hardto-find defects in honeycomb composite. The BondMaster 600 bond tester also displays real-time readings showing signal amplitude or phase, and its new “Scan” view enables you to monitor the probe amplitude and phase over time, aiding in the detection of small disbonds.

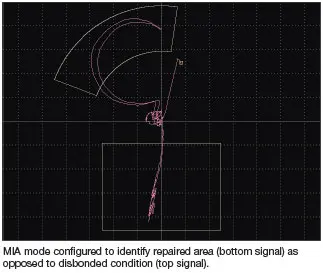

Identification of Repaired Areas (Potting) in Honeycomb Composite

Identifying repaired areas on an aircraft’s rudders or fuselage can be a challenge, especially when they are painted. With certain inspection methods, such as thermography, repairs can generate false indications. However, MIA mode can resolve this problem. Because the repaired area is generally stiffer, its mechanical impedance contrasts well with good areas as well as with disbonds. The improved MIA method offered by the BondMaster 600 bond tester enables you to identify repaired areas with ease through a simple phase analysis of the MIA signal in the X-Y view.

Identifying repaired areas on an aircraft’s rudders or fuselage can be a challenge, especially when they are painted. With certain inspection methods, such as thermography, repairs can generate false indications. However, MIA mode can resolve this problem. Because the repaired area is generally stiffer, its mechanical impedance contrasts well with good areas as well as with disbonds. The improved MIA method offered by the BondMaster 600 bond tester enables you to identify repaired areas with ease through a simple phase analysis of the MIA signal in the X-Y view.

Complete Inspection, Archiving, and Reporting Solution

Simplified Workflow for Any Level of User

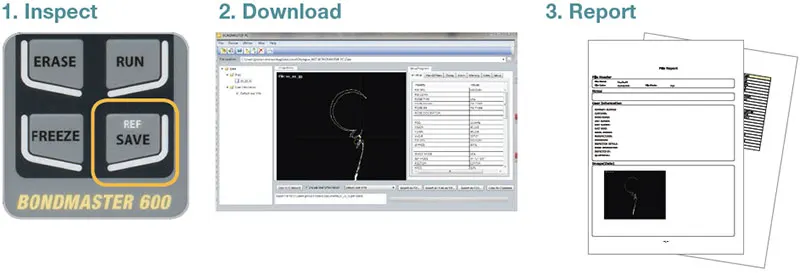

The BondMaster 600 bond tester offers a completely streamlined and straightforward process for tracking your inspection results. Built-in features such as a large storage capacity (up to 500 data and program files) and an onboard file preview have been created to facilitate the inspection process, from start to finish. A typical workflow consists of a few simple steps: save your results during the inspection process, download the saved files to the new BondMaster PC viewing software, instantly generate a full inspection report using the new “Export all files as PDF” function, and archive the report if required.

The BondMaster 600 bond tester is offered in two models to accommodate the varying needs of composite bond testing. The basic model includes all pitch-catch capabilities while the B600M model features all bond testing inspection methods. The upgrade from basic to multimode can also be performed remotely. Both BondMaster 600 bond tester models are compatible with existing Olympus BondMaster probes, including those equipped with the POWERLINK technology. Optional adaptor cables are available to enable compatibility with probes from other manufacturers.

| Application | Recommended Method |

| General Honeycomb Composites Skin-to-Core Disbonds | Pitch-Catch (RF or IMPULSE) |

| Honeycomb Composites Skin-to-Core Disbonds in Tapered Structures or Non-Constant Geometries | Pitch-Catch (Swept) |

| Smaller Skin-to-Core Disbonds in Honeycomb Composite | MIA |

| Identification or Repaired Areas in Honeycomb Composite | MIA |

| General Detection of Delamination in Composite | Resonance |

| Inspection of Metal-to-Metal Bonds | Resonance |

| Feature | B600 (basic) | B600M (multimode) |  |

| Frozen-Signals Calibration | Y | Y | |

| Real-Time Readings | Y | Y | |

| Application Selection | Y | Y | |

| POWERLINK Probe Support | Y | Y | |

| Pitch-Catch RF and Impulse Modes | Y | Y | |

| Pitch-Catch Swept | Y | Y | |

| Mechanical Impedance Analysis (MIA) Mode | N | Y | |

| Resonance Mode | N | Y (cable included) | |

| Calibration Menu (Resonance and MIA Modes) | N | Y |

General |

|

| Overall Dimensions (W × H × D) | 236 mm × 167 mm × 70 mm (9.3 in. × 6.57 in. × 2.76 in.) |

| Weight | 1.70 kg (3.75 lb), including lithium-ion battery |

| Standards or Directives | Mil Standard 810G, CE, WEEE, FCC (USA), IC (Canada), RoHS (China), RCM (Australia and New Zealand), KCC (South Korea) |

| Power Requirements | AC Mains: 100 VAC to 120 VAC, 200 VAC to 240 VAC, 50 Hz to 60 Hz |

| Inputs and Outputs | One USB 2.0 peripheral port, one standard VGA analog output port, one 15-pin I/O port (male) with analog output, 3 alarm outputs. |

Environmental Conditions |

|

| Operating Temperature | –10 °C to 50 °C (14 °F to 122 °F) |

| Storage Temperature | –20 °C to 60 °C (–4 °F to 140 °F) [with batteries] and –20 °C to 70 °C (–4 °F to 158 °F) [without batteries) |

| IP Rating | Designed to meet requirements of IP66 |

Battery |

|

| Battery Type | Single lithium-ion rechargeable battery or AA size alkaline batteries (in an 8-cell holder) |

| Battery Life | Between 8 and 9 hours |

Display |

|

| Size (W × H; Diagonally) | 117.4 mm × 88.7 mm; 146.3 mm (4.62 in. × 3.49 in.; 5.76 in.) |

| Type | Full VGA (640 × 480 pixels) color, transflective LCD (liquid crystal display) |

| Modes | Normal or Full screen, 8 color schemes. RUN key to toggle between screen modes. |

| Grids and Display Tools | Choice of 5 grids, crosshairs (X-Y views only) |

Connectivity and Memory |

|

| PC Software | BondMaster PC software included in base Bond-Master 600 kit. BondMaster PC enables viewing saved files and printing reports |

| Data Storage | 500 files featuring user-selectable onboard preview. |

Interface |

|

| Languages | English, Spanish, French, German, Italian, Japanese, Chinese, Russian, Portuguese, Polish, Dutch, Czech, Hungarian, Swedish, and Norwegian. |

| Applications | Application Selection menu for easy and rapid configuration in all modes. |

| Real-Time Readings | Choice of up to 2 real-time readings measuring signal characteristics (list depends on selected mode) |

Probes Types Supported |

|

| Probe Types | Pitch-Catch, Mechanical Impedance Analysis (MIAB600M only), and Resonance probes (B600M only). The instrument is fully compatible with BondMaster POWERLINK and non-POWERLINK probes, as well as those of other main probe and accessory suppliers |

Bond Testing Specifications (All BondMaster Models |

|

| Probe Connectors | 11-pin Fischer |

| Gain* | 0 dB to 100 dB in 0.1 or 1 dB increments |

| Rotation* | 0° to 359.9° in 0.1° or 1° increments |

| Scan View* | Variable from 0.520 s to 40 s |

| Low Pass Filter* | 6 Hz to 300 Hz |

| Probe Drive | LOW, MEDIUM, and HIGH user-adjustable settings |

| Variable Persistence* | 0.1 s to 10 s |

| Variable Display Erase* | 0.1 s to 60 s |

| Available Alarm Types* | 3 simultaneous alarms. Choices include BOX (rectangle), POLAR (circle), SECTOR (pie), SCAN (timebased), and SPECTRUM (frequency response |

| Reference Dots* | Up to 25 user-defined dot recordings |

Pitch-Catch Specifications (All BondMaster Models |

|

| Supported pitch-catch modes | User-selectable mode. Choice of RF (toneburst), Impulse (envelope), or Swept (frequency sweep) |

| Frequency Range | 1 kHz to 50 kHz (RF, Impulse) or 1 kHz to 100 kHz (Swept) |

| Gain | 0 dB to 70 dB in 0.1 or 1 dB increments |

| Gate | 10 μs to 7920 μs, adjustable in 10 μs steps. New Auto Gate mode automatically detects maximum amplitude |

| Frequency Tracking* | Up to 2 user-adjustable markers to monitor 2 specific frequencies from the Swept figure |

| Mechanical Impedance Analysis (MIA) Specifications (B600M Only) | |

| Calibration Wizard | Calibration menu to determine the best frequency for the application based on simple “BAD PART” and “GOOD PART” measurements |

| Frequency Range | 2 kHz to 50 kHz |

| Resonance Specifications (B600M Only) | |

| Calibration Wizard | Calibration menu to determine the best frequency based on the probe response |

| Frequency Range | kHz to 500 kHz |

|

Standard Inclusions The BondMaster 600 bond tester comes with the following standard inclusions:

Items included in all BondMaster 600 models†: BondMaster 600 instrument with factory-installed hand strap, getting started manual, calibration certificate, rigid transport case, DC charger with power cord, Li-ion battery, AA battery tray, USB communication cable, MicroSD memory card and adaptor, pitch-catch and MIA probe cable, and BondMaster PC software and product manuals disc. Additional items included in BondMaster 600M model only: Resonance probe cable. †Standard inclusions may vary depending on your location. Contact your local distributor |

|